I was looking forward to selling my previous Lun Hyper wheelset so I could invest in something new. While many overseas companies are fully aboard the carbon-spoke trend, I wanted a more traditional wheel with steel spokes paired with a modern, wider rim. Light Bicycle offered the customization I was looking for—without an overly exorbitant price tag.

The Custom Order

When ordering the wheels, Light Bicycle had a nice interface to show the order status as well as who was working on each stage. The feedback from the point of contact via email whenever a question or concern was raised was very quick.

The order was placed August 7, 2025

It was shipped September 30, 2025

It was delivered October 20, 2025

The Custom Wheels

HUB-F DT SWISS 240 EXP Black 12 / 100mm straight pull Center lock 24H

HUB-R DT SWISS 240 EXP Black 12 / 142mm straight pull Center lock 24H EXP 36 Shimano Road 11S Alloy

Sapim CX Ray

Sapim Brass Black nipples

WR50 disc Standard Hook UD Paintless Disc 24H External Hole With Drain Holes No Access Holes 5 Years

WR50 disc Standard Hook UD Paintless Disc 24H External Hole With Drain Holes No Access Holes 5 Years

Centered (Traditional)

+4 additional spokes

+10% discount for the 14 year anniversary sale

+free 14 year anniversary backpack gift.

$1,223.40

NOTE: Oversees shipping was done via MTS-Sea (Multimodal Transport Service) and UPS handled the delivery upon arrival at the port of Los Angeles. I did not have to pay any additional import tariffs.

The rims look to be very solid. The fairing is solid and no imperfections could be found on the outside. There are some wheels in which you can feel how thin the side of the rim is. That is not the case for these. The holes that were drilled look to be very clean. These rims were not drilled for nipple access holes. Even though it will make nipple replacement a little more challenging, the rim will be just a little more stiff. The finish is also a unique carbon shimmer.

Tires

The tires are GP5000 S 30mm on the rear and GP5000 AS 28mm on the front. The front tire looks like it could have been a little narrower for a more aero rim profile.

Tires measured 32.67mm rear and 30.58mm front with a digital caliper.

Reservations

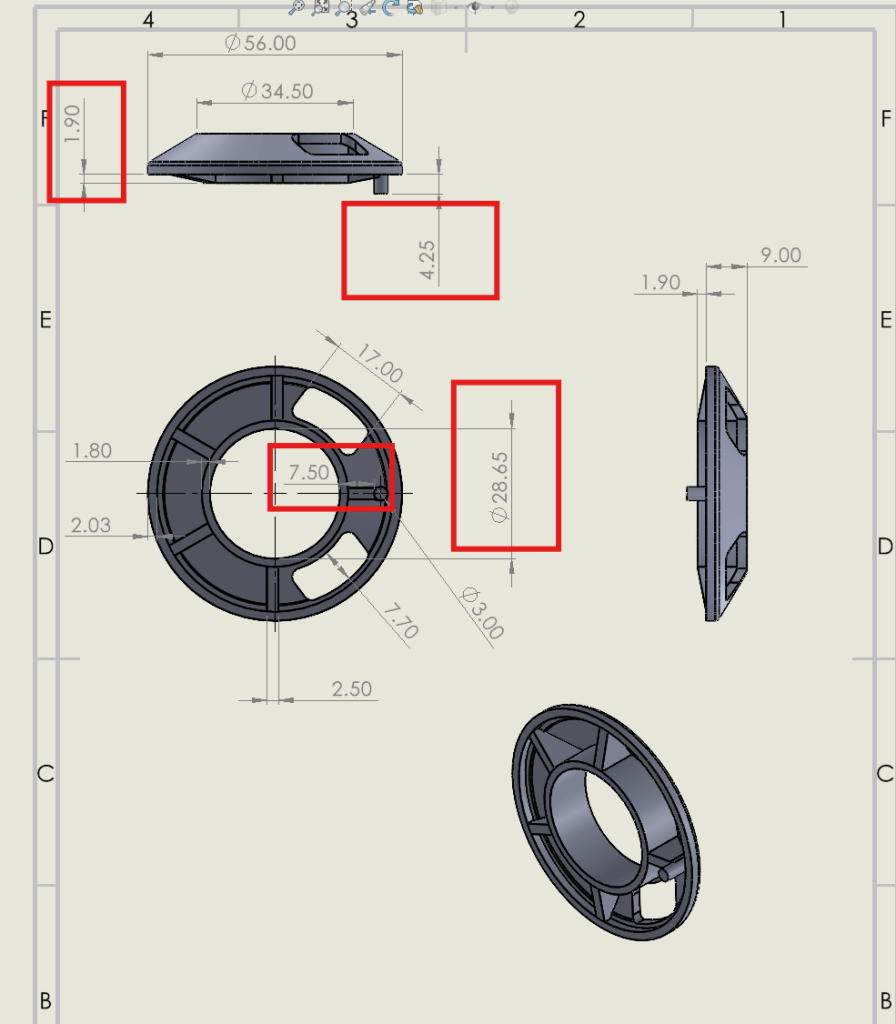

This wheelset is full custom, with the rim being made to order and then built up. After all this time and energy and money spent, the freehub came with a defect. When the wheel is installed and the axle threaded in, the freehub becomes seized and does not rotate in either direction. The wheel spins smooth otherwise. Turns out the shim/spacer in the freehub was undersized. It rattles when shaken as shown in the picture. This would explain the seizing issue. With the axle threaded, it would compress the freehub due to the gap made by the undersized spacer.

Light Bicycle was unable to provide any input or assistance. DT Swiss however was able to confirm the issue and agreed to send a new freehub body. Just need to wait a little bit longer.

Additionally, with the DT Swiss ratchet patent expired, other companies are already making improvements to the design. For instance, Elite has new hubs with a conical ratchet. DT swiss also has their DEG hubs but this technology has not trickled down into road hubsets yet.

I was also curious why the rear hub lacing was not done perpendicular to the hub for a more tangential and direct torque transfer. Perhaps the increased spoke length was an issue. Or the angled spoke might give the wheel more spring.

Lastly, the rear hub axle is anodized for added durability. However, the front hub axle is not. Light Bicycle was unable to provide any explanation on this.

Update

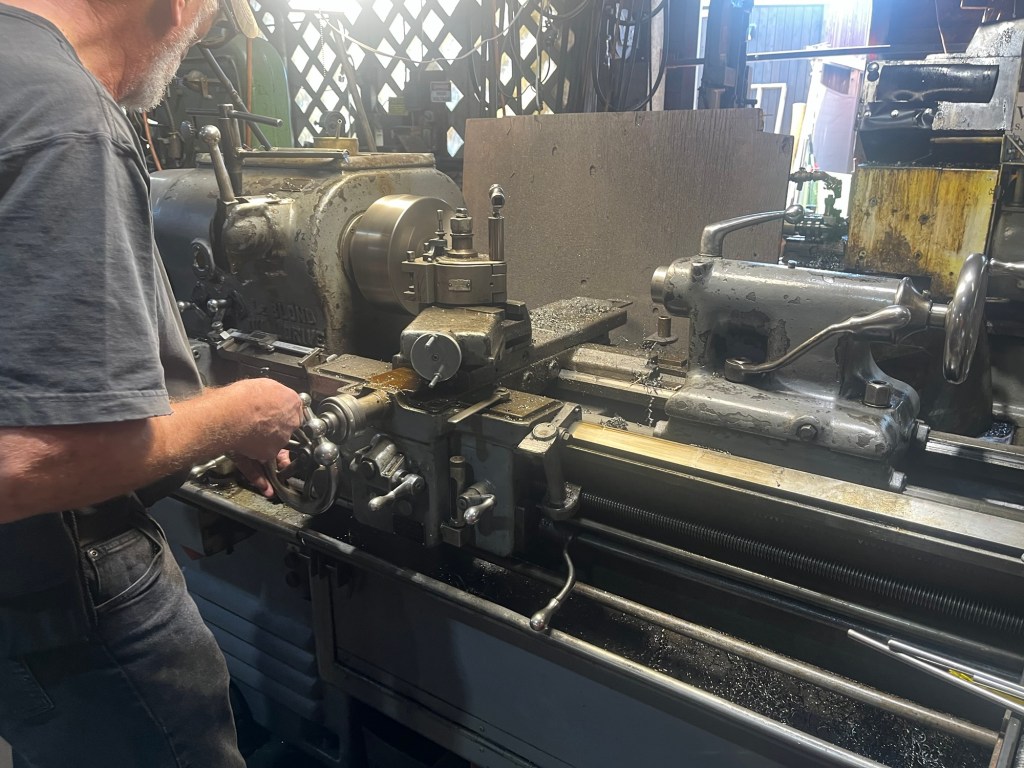

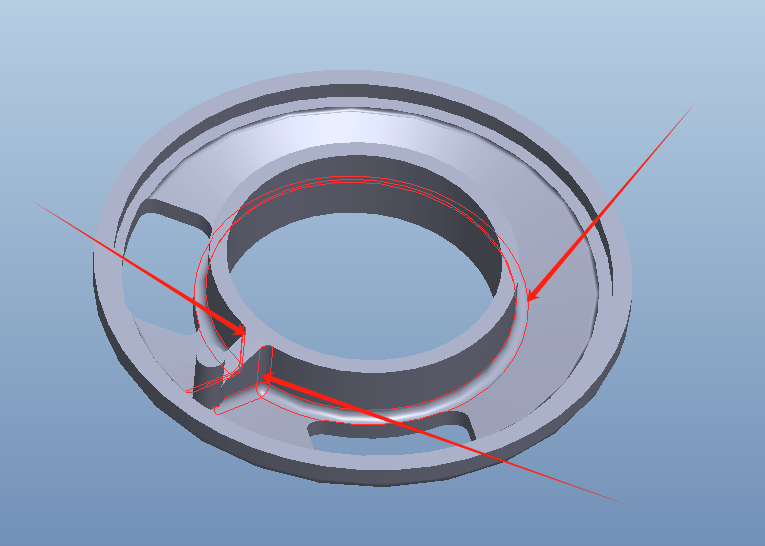

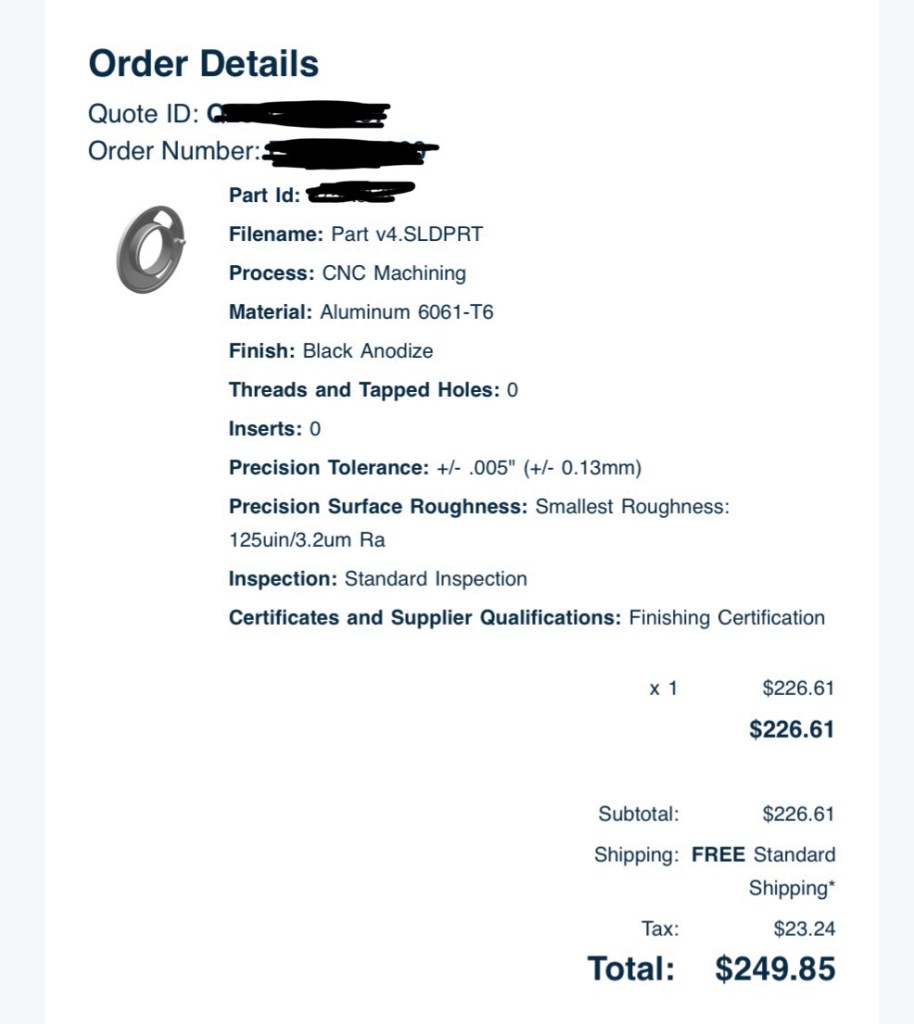

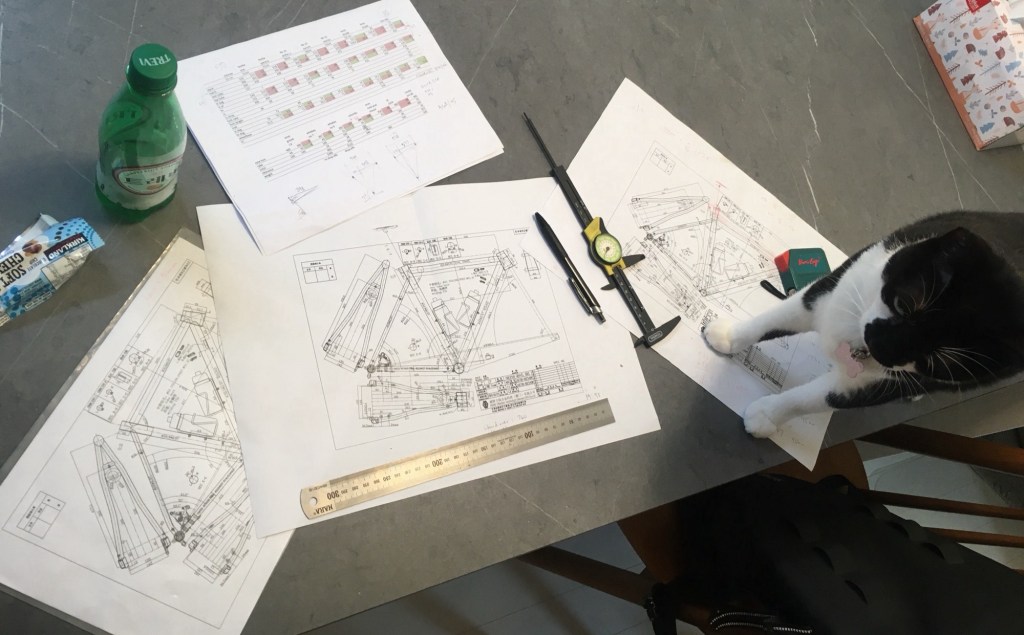

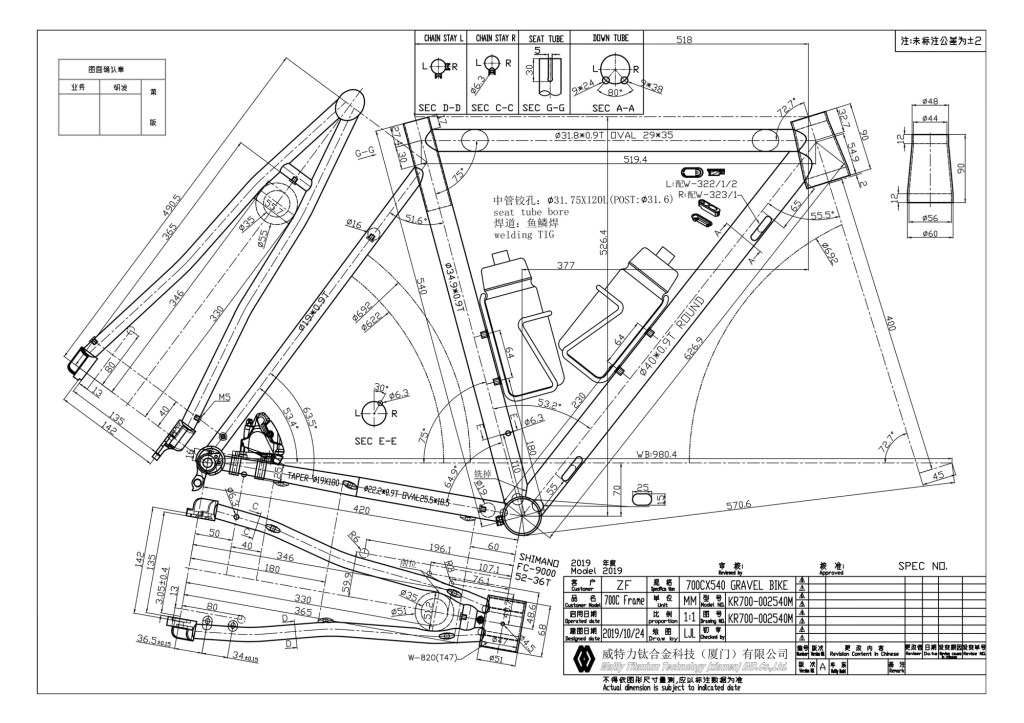

While waiting for a new freehub to arrive from DTSwiss, I reached out to a local machine shop to see if they could help in sorting out a new spacer of correct dimensions. After sizing everything up, the owner was able to get one made on the spot. The one installed was about 1/8″ too short.

It’s amazing that places like this still exist, albeit they’re under a lot of pressure of being phased out. Once installed, the wheel worked. Support your local industry.