When choosing to build a bike with internal routing, the cockpit can become complex and congested with multiple hoses and lines all going into the down tube. A lot of factory brand bikes that utilize internal routing come with their own proprietary options that are not designed to be interchangeable. Even aftermarket products like Enve have their own unique system. The integrated cockpit designs that are currently available require that the headset and stem, and sometimes handlebars, be used together as a set in order to work. This is not ideal if one wishes to choose a stem and handlebar separately, as has always been done for bike fitting purposes.

For my titanium frame, I wanted to have a stem with a zero degree rise and this design was not available, with integrated stems ranging from 12 to 6 degrees. This led me to opt for a headset design that would allow for cables to be run through the top cap such that a standard road stem and handlebars could be used. This would also simplify the installation slightly since cables would not need to be run through the handlebars and/or stem. It would also make it easier to swap stems and/or handlebars in the future. There were not many options available that allowed for this piecemeal installation method. The Cervelo mountain bike headset assembly seemed to be a viable option, but it did not come without its issues.

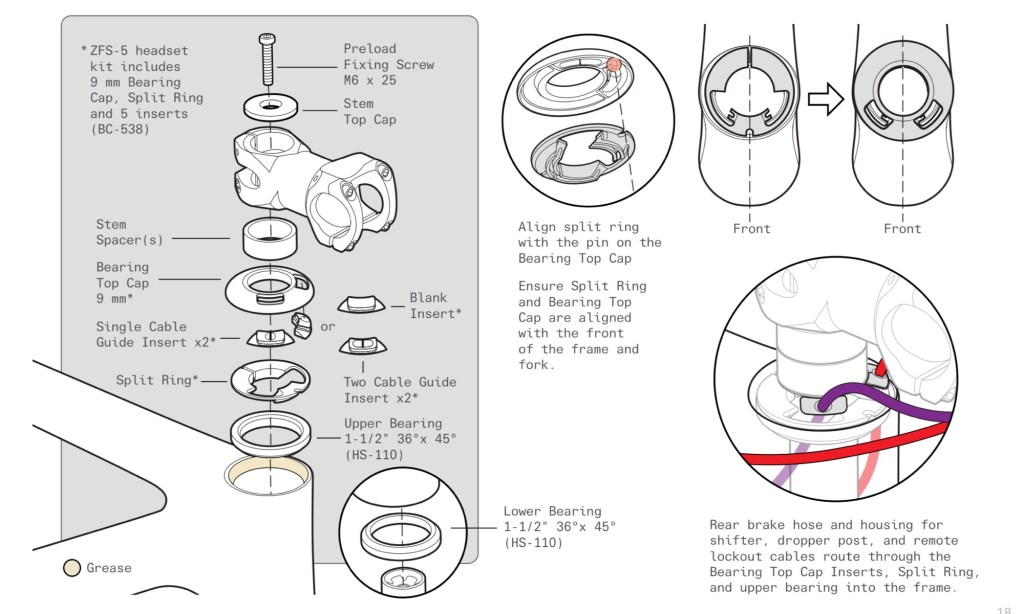

A common feature of all integrated headset/handlebar products is the interlocking parts of the headset. The top cap and bearing race are linked together via the protruding tab on the bottom of the top cap (shown in the installation manual). This allows for the top cap, bearing race, and cables to move uniformly, preventing the cables from being twisted when steering.

The issue that arose with the titanium frame was that the top cap was not compatible due to the dimensions of the headtube.

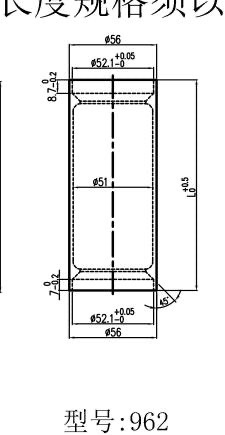

The diagram shows the dimensions of the headtube. There is 8.7mm above the taper where the bearing will sit.

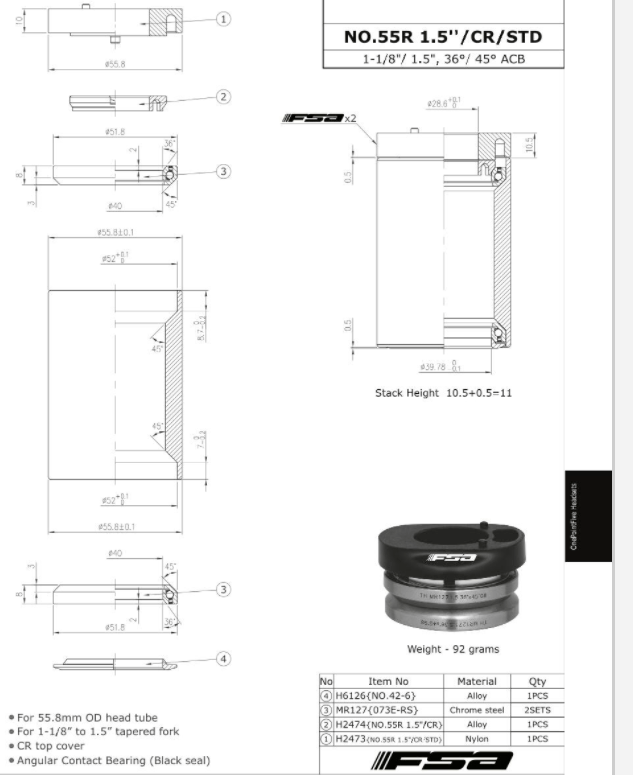

The diagram from FSA No. 55R shows the bearing height as 8mm, leaving a gap of 0.7mm between the top of the bearing and the top cap for my frame.

The cervelo bearing race, when inserted into the upper bearing, does not come up flush with the top of the headtube. The upper cap also does not have any demension that extends below the bottom surface meaning that the cap, when installed, cannot touch the bearing race and therefore the interlocking tab cannot engage. The diameter of the top cap was also larger than the diameter of the headtube, and the inner diameter, for the steerer, was a loose fit.

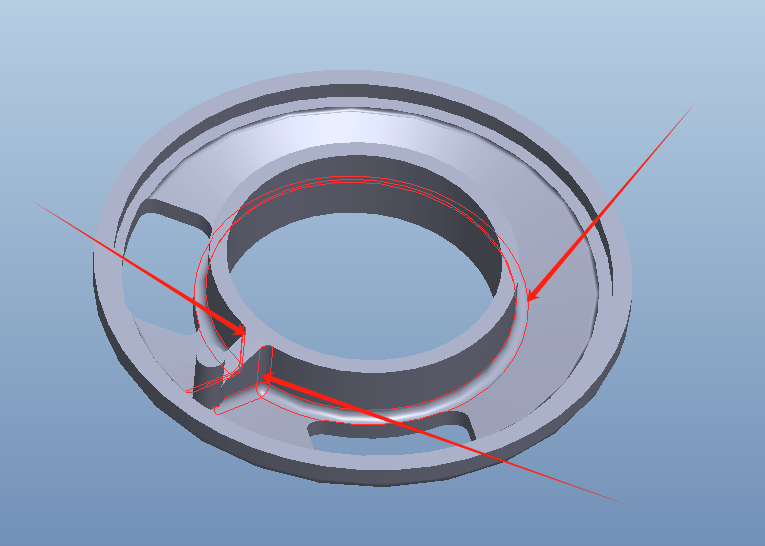

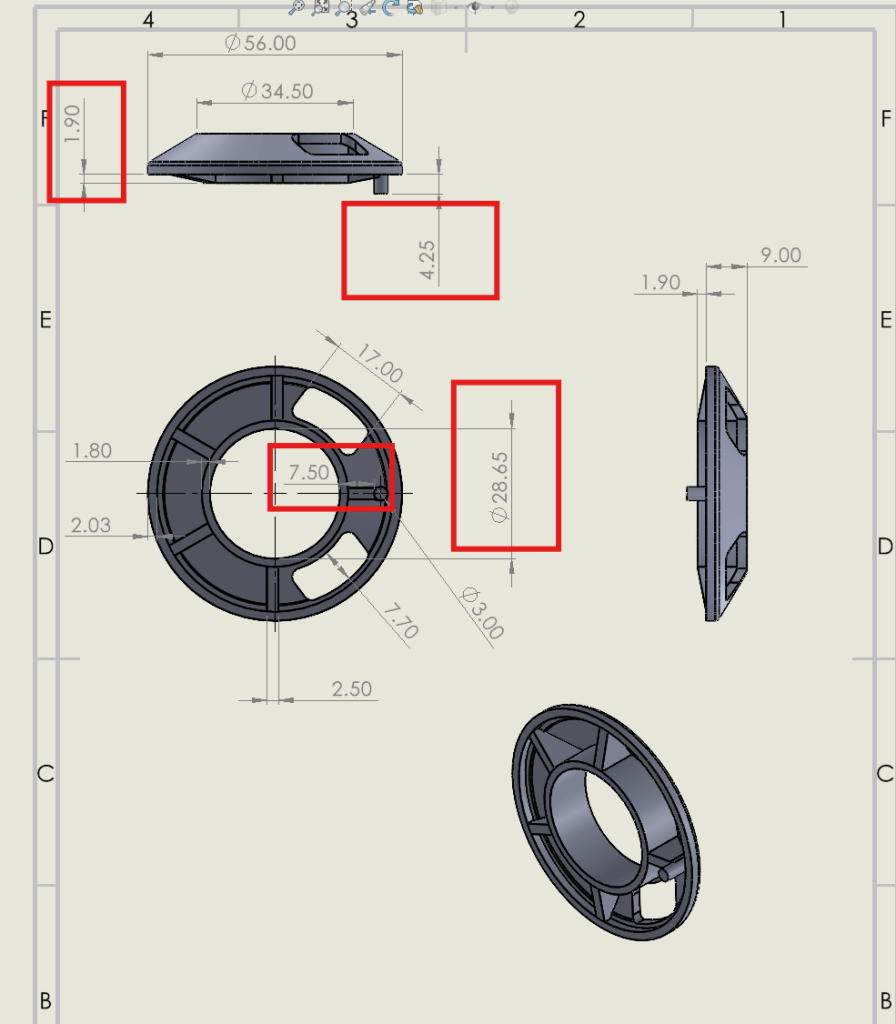

The top cap was redesigned in solid works such that the top cap would extend below, and the tab even further, allowing it to fit with the dimensions of the headtube and crown race.

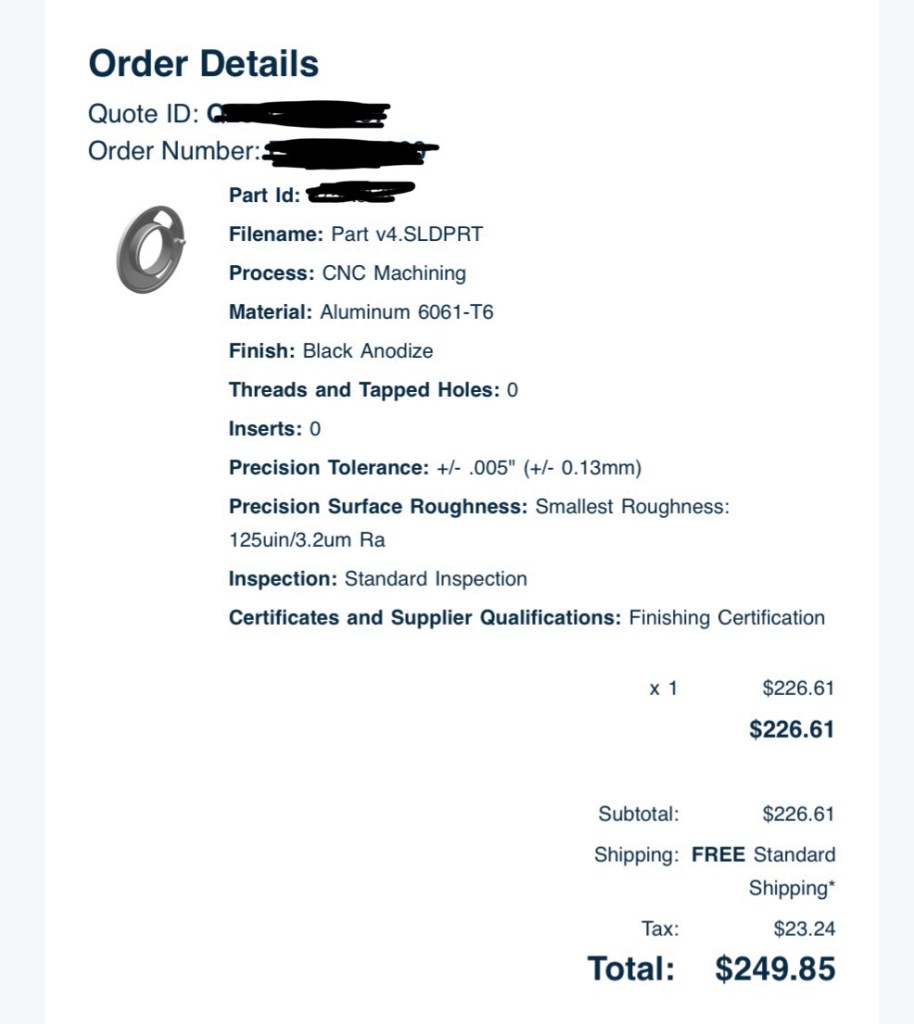

The Final Design

After 3D printing and prototyping the top cap design, a final drawing was made and sent to be CNC’d out of Aluminum. This will require that the brake hose will need to be uninstalled and re-routed through the opening. All-in-all, a simple installation for a permanent solution to running cables internally.