Having lived in many small apartments, creating safe and secure bike storage for multiple bikes is a challenge. The end of this post will have details about an adaptable hanging and sliding bike storage design.

A lot of mainstream bike storage solutions can be less than ideal when space is limited, such as the wall mounted bike racks.

These static wall-mounted bike racks have their time and place. They’re great if you have one or two bikes, and the floor and wall area to spare. When installed at the proper height, they can be easy to take the bike on and off. Furthermore, this style of rack can be a nice alternative bike stand when doing any type of bike maintenance. It can also be pleasing having the bike on full display.

There are a wide range of static, wall mounted bike racks available. One thing they have in common is that once installed, that is where the bike will stay and cannot easily be moved or placed anywhere else.

When working and living in more confined spaces, a hanging bike rack can help save wall space as well as having a smaller footprint area. It takes some strength to be able to hoist the bike off the hook, but properly leveraging the bike can make this easier and safer.

Although this type of storage allows for some degree of rearranging by sliding the hooks, the rack itself is still static. When using this type of storage rack, it would be important to consider what type of bike(s) would be hung since the rack should have enough of a setback from the wall to ensure the bike can fit.

Compared with other static wall mounted racks discussed earlier, this hanging bike rack can store upwards of 5 bikes in the same amount of space.

Sliding Rack Design

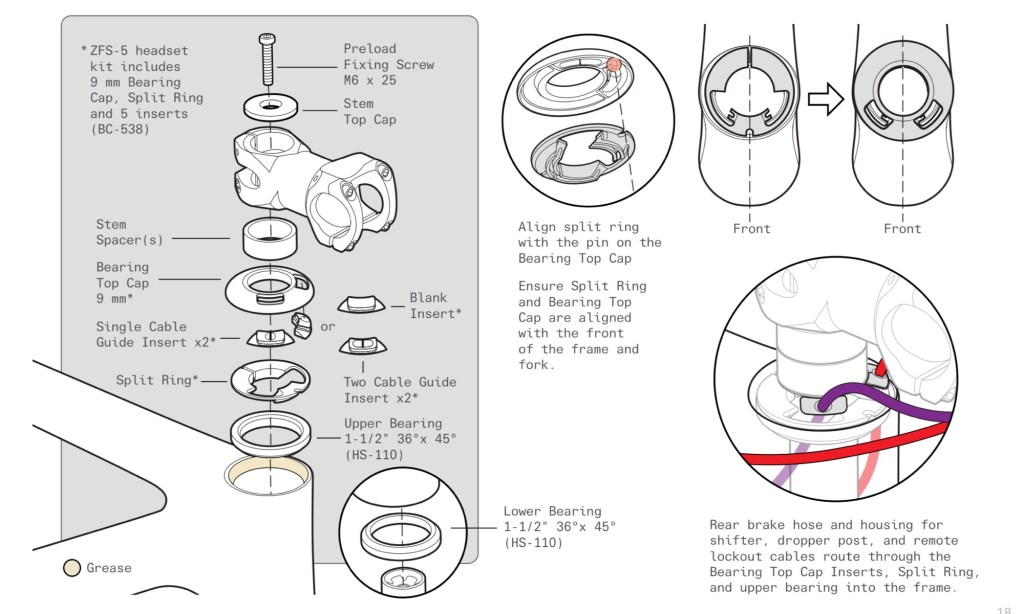

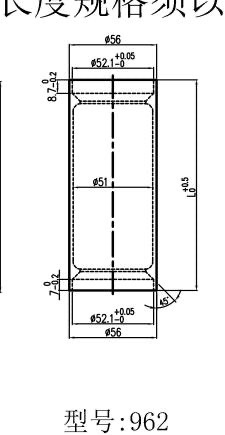

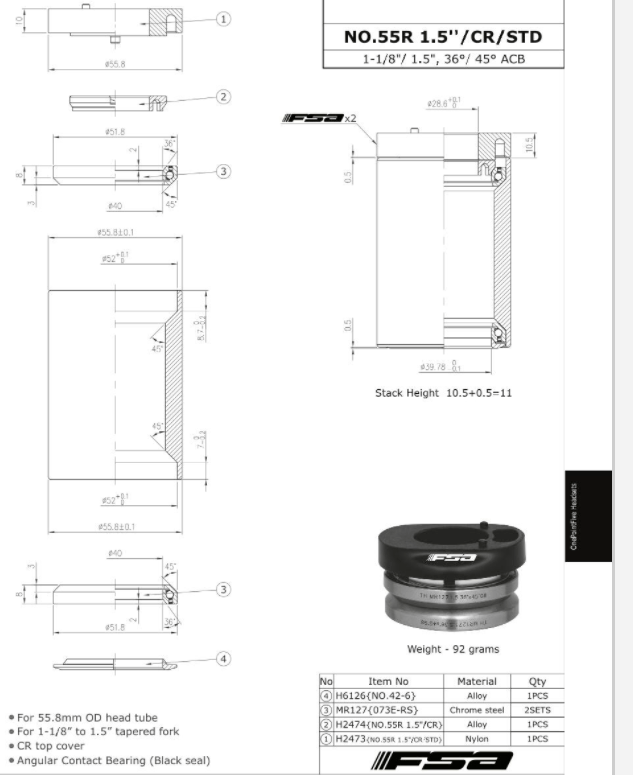

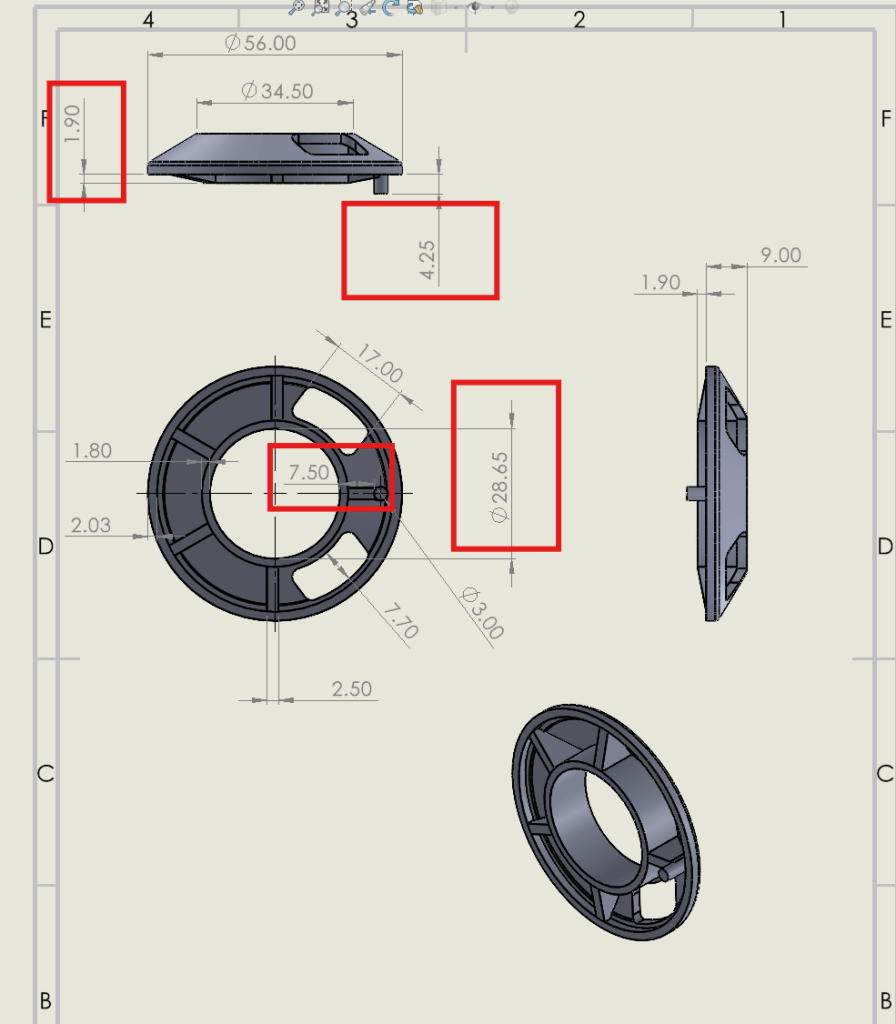

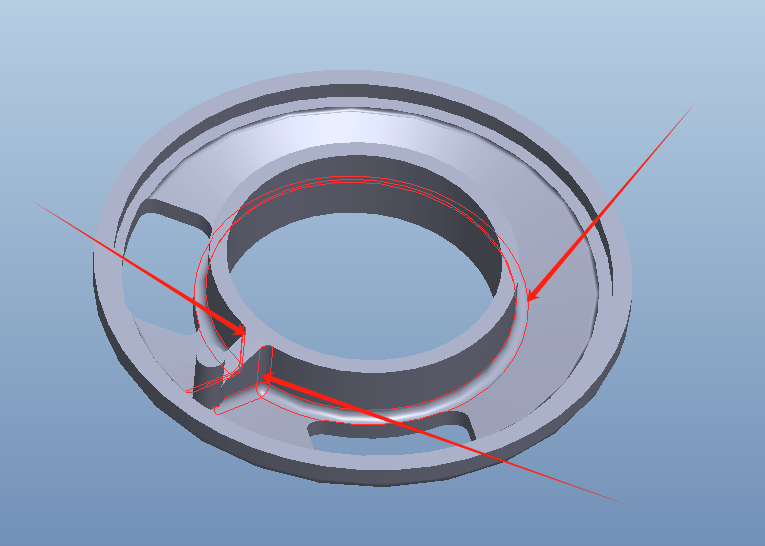

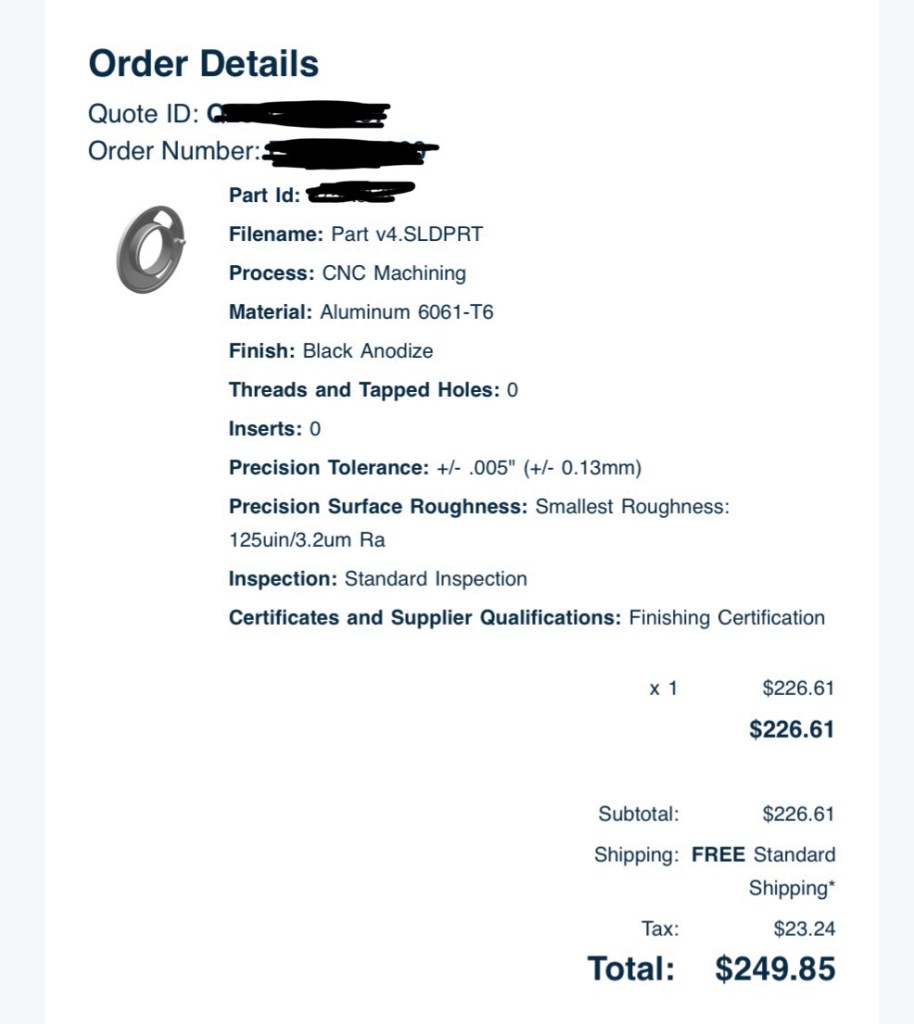

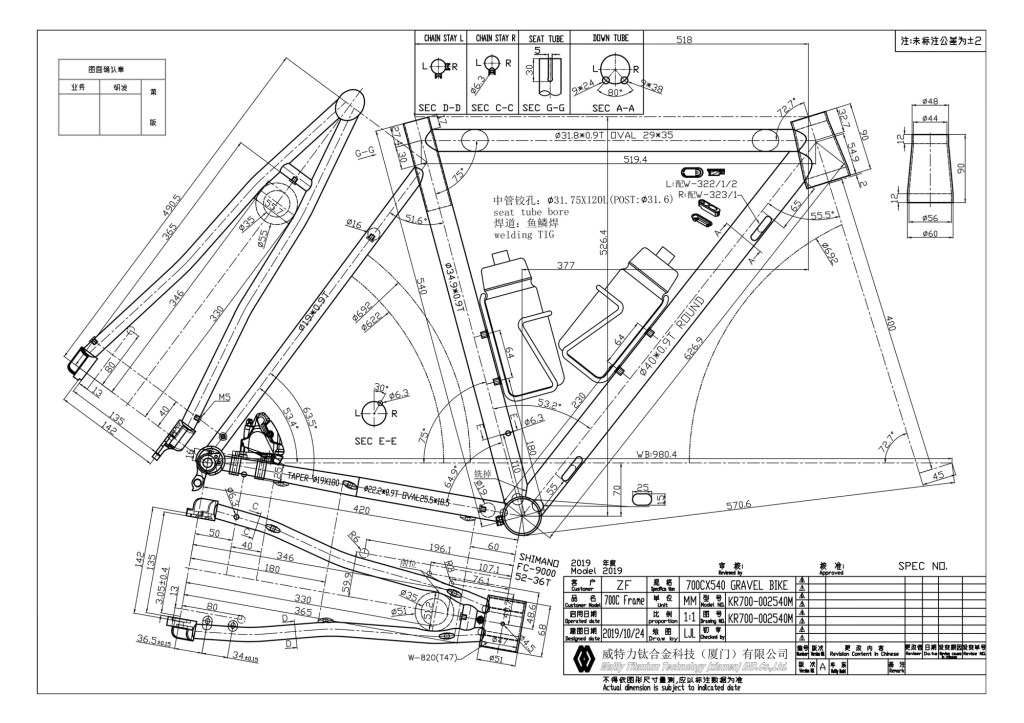

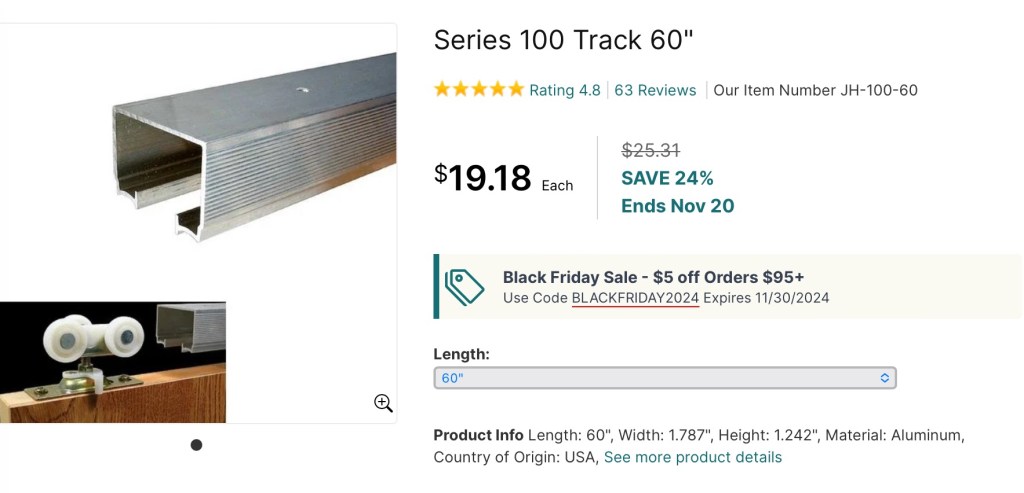

This rack uses an aluminum extrusion rail, similar to those used with sliding french doors. The cross section allows for a hanger to be installed and the weight properly distributed to the rails. Rails can be found online or in local hardware stores for a very reasonable price.

Note. It is important to install the rail into a solid wood ceiling member, utilizing all mounting holes for support strength.

Although not the most elegant solution, a nut and bolt can suffice when hanging heavy duty hooks. The bolt head and nut keep the bolt aligned in the rails, preventing it from turning or coming loose. A heavy duty hook can be placed around the bolt and support the bike. The bolts can also slide along the rail to allow for the bikes to be placed at any suitable point.

Variable Ceiling Conditions

If the ceiling heights are variable or if the ceiling can not be screwed into, or if you want something completely modular, closet tension racks can offer a more adaptable solution.

The rods are compressed between the floor and ceiling and the horizontal rod heights are also adjustable. These designs are made to be adjustable in order to accommodate a wide range of closet and interior space dimensions. The rack shown below was used in an apartment where the walls were concrete. The tension rack was sturdy and very adjustable.

When it comes to bike storage, there’s no one-size-fits-all solution. The limitations of the space and personal preferences will help find the best bike storage solution.